#004

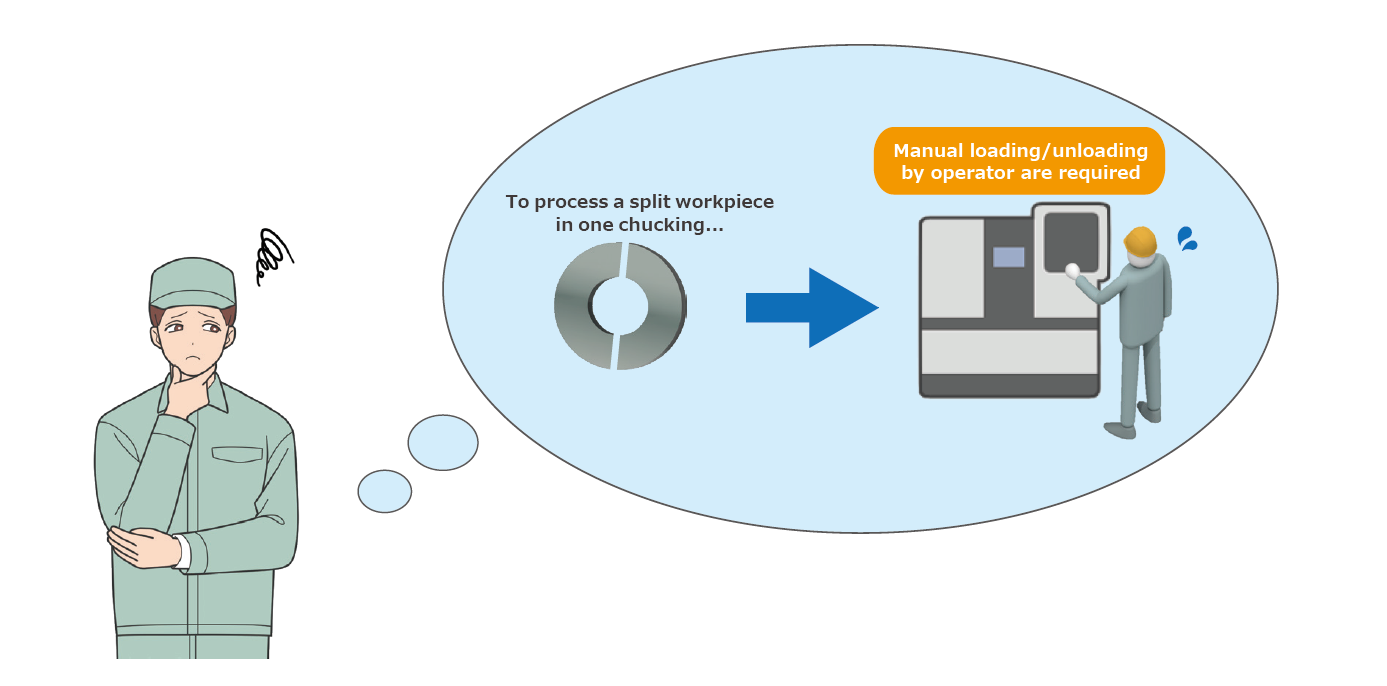

"We want to efficiently cope with daily changing production instructions in order to increase productivity!"

⚡Issues faced by the customer⚡

1.They have to change the program manually at least 10 times a day.

The production volume also fluctuates ranging from 1 to 1,000 pieces.

Therefore, many man-hours for changeovers are required, resulting in poor productivity.In addition, many mistakes occur during changeovers due to human errors.

2.Since they have many types of workpieces, they need to separate machines for each group of types, and some machines may not be used depending on the day.

💡Benefits that can be provided by our "MT100" are as follows:

1.The 2D code allows daily workpiece changeovers to be most efficiently streamlined, leading to a great productivity improvement!

2.Enables a fully automatic machining of a wide variety of workpieces without changeovers by using the servo unloader and MT100 that can accept up to 45 tooling!

Our proposals to solve the customer’s problems are as follows.

📝Proposals

1.The 2D code allows daily workpiece changeovers to be most efficiently streamlined, leading to a great productivity improvement!

At the beginning of a working day, the 2D code is created to output the data on the number of workpieces to be processed and the relevant machining programs for that day in order to respond to daily changing production schedule. All the operator has to do is to enter the 2D code into the machine. Then, fully automatic machining operations are performed on various types of workpieces that need to be processed for that day without changeovers.

Also, that eliminates the operator’s program change manually, so the mistakes when changeovers will be dramatically reduced.

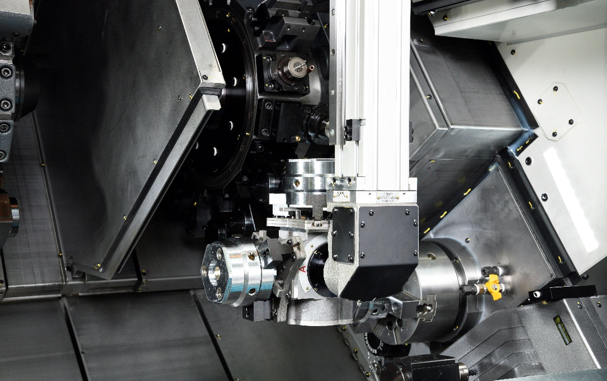

2.Enables a fully automatic machining of a wide variety of workpieces without changeovers by using the servo unloader and MT100 that can accept up to 45 tooling!

Not only can you change the machining programs and production volume, but you can also change the workpiece transfer program instantly.

In addition, by using MT100 that can incorporate up to 45 tooling, it is possible to eliminate or reduce the tool change for each workpiece.

✨Productivity

Due to quick changeovers, the man-hours for changeovers have been greatly reduced!

Moreover, the easy changeovers has allowed both the operating time and the production volume to increase, providing room for handling new type of workpieces!

✨Space saving

Since the MT100 can handle all types of workpieces at the customer, which had been separated into multiple types and machined with several lathes, it has contributed to space saving in the factory!

❄Season’s Greetings❄

Dec 26, 2024

#20 Improving a production line where manual operation was thought to be necessary!

This is an example of Muratec’s unique technological approach with wide-ranging design experts!

Dec 26, 2024

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

❄Season’s Greetings❄

Dec 26, 2024

#20 Improving a production line where manual operation was thought to be necessary!

This is an example of Muratec’s unique technological approach with wide-ranging design experts!

Dec 26, 2024

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

| Company Name |

Murata Machinery, Ltd. Japanese Name : Murata Kikai Kabushiki Kaisha |

|---|---|

| Established | July 1935 |

| Main office | 136, Takeda-Mukaishiro-cho, Fushimi-ku, Kyoto 612-8418 Japan |

| Branch office (Japan) | Tokyo, Osaka, Nagoya |

| Factories (Japan) | Inuyama, Kaga, Ryuo, Oita, Ise, Gifu |

| President | Daisuke Murata |

| Products |

Textile Machinery, Machine Tools, Sheet Metal Machinery, Automated Systems, Clean FA Systems, Communication Equipment |

| Capital | JPY 900 million |

| Sales |

Consolidated: 391,800 million yen Non-Consolidated: 304,300 million yen (as of March 31, 2022) |

| Employees | 3700 [Group; 8100 ](as of April, 2022) |