We would like to introduce our bar work dedicated machines that are attracting attention in Europe.

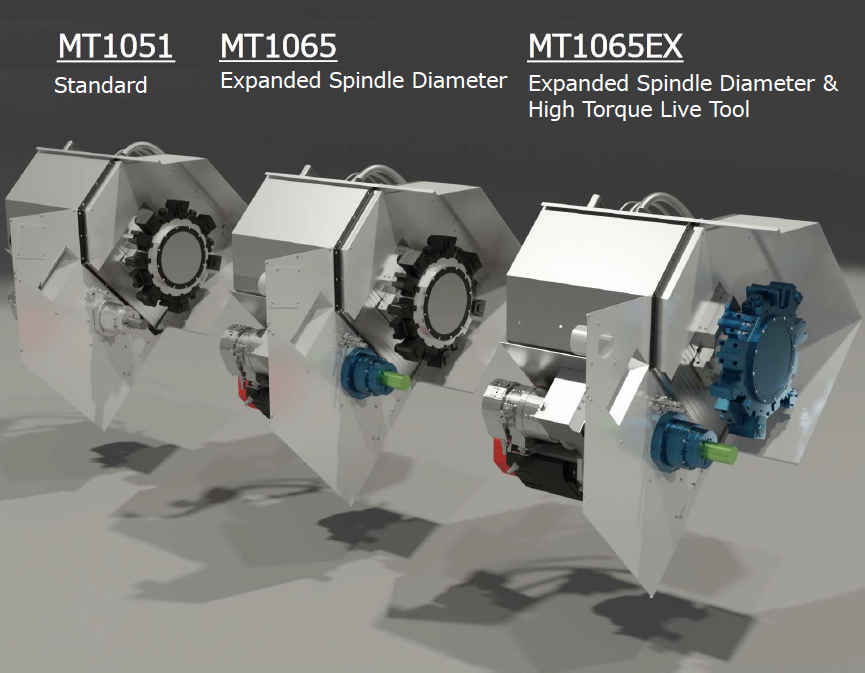

Equipped with 2 spindles, 2 turrets, Y-axis and live tools, the CNC turning centers are available in three models:

MT1051 (standard type), MT1065 (expanded spindle diameter type), and MT1065EX (expanded spindle diameter & high torque live tool type), depending on the user needs.

Although our turning centers have basically been designed to work with a gantry loader for automatic transfer of workpieces in chuck work,

the MT1051, MT1065, and MT1065EX machines have been developed to meet customers' individual needs as a simple machine dedicated to bar work, with their basic processing capabilities fully utilized.

Based on our efficient development concept for bar machines, they have achieved both low-cost and high-flexibility operations.

・The chip conveyor can be set to discharge cutting chips from the right side or rear of the machine.

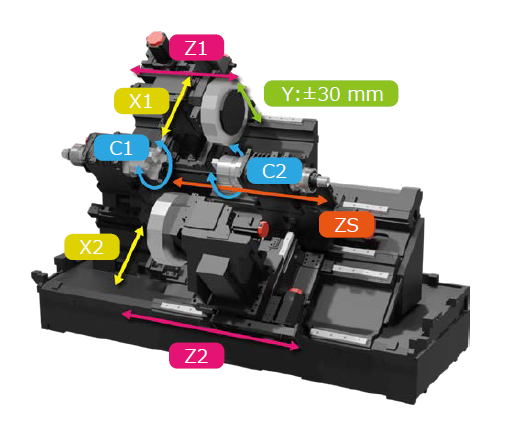

・Both the upper and lower turrets can access to the left and right spindles.

【Upper left turret】X, Y and Z axis and live tool function.

【Lower right turret】X and Z axis and live tool function.

Three variations are available through combination of bar diameter, spindle motor, number of tools (turret specifications), and live tool output.

An appropriate type can be selected depending on the materials to be processed and individual customers' needs.

・MT1051 (Standard type)

・MT1065 (Expanded Spindle Diameter type)

・MT1065EX (Expanded Spindle Diameter & High Torque Live Tool type)

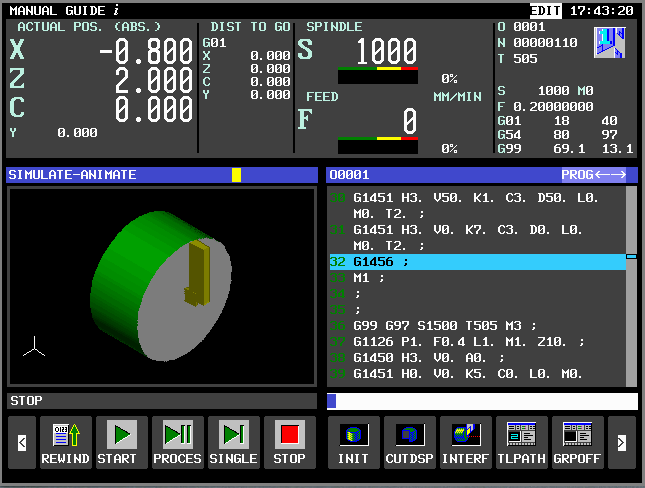

The Fanuc programming guidance function "FANUC MANUAL GUIDE i" is installed as a standard function,

making it easy to create programs for kissing, material supply, and finished parts unloading cycles in addition to machining programs.

・Simply following the guidance allows the machining cycle to be completed without referring to the manual.

・Operational simulation is displayed on the NC screen, making it possible to verify the program immediately after it is created.

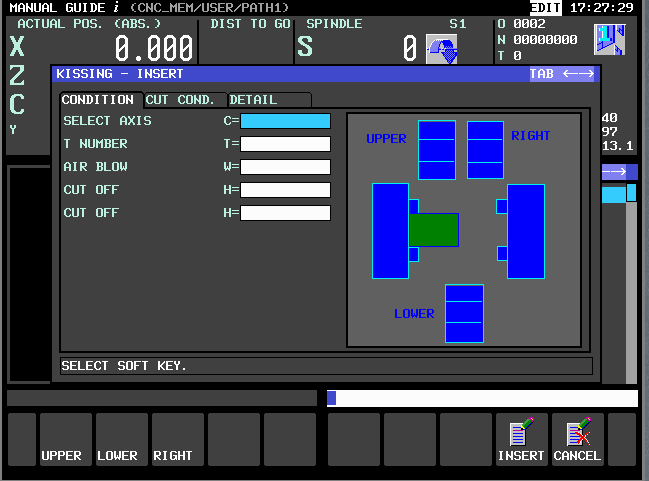

・Muratec's unique kissing and finished parts unloading cycles can also be programmed.

・Processes and operations performed by each turret are clearly displayed.

〈Machining Program Screen 〉 〈Kissing Cycle Screen〉

Muratec's latest thermal displacement compensation system is installed as standard equipment.

Sensors are placed in various locations in the machine, enabling real-time monitoring and feedback for reducing the effects of thermal displacement in order to ensure stable operations.

For more information about this product or request for a catalog, please feel free to contact us through the Contact link on this website.

❄Season’s Greetings❄

Dec 26, 2024

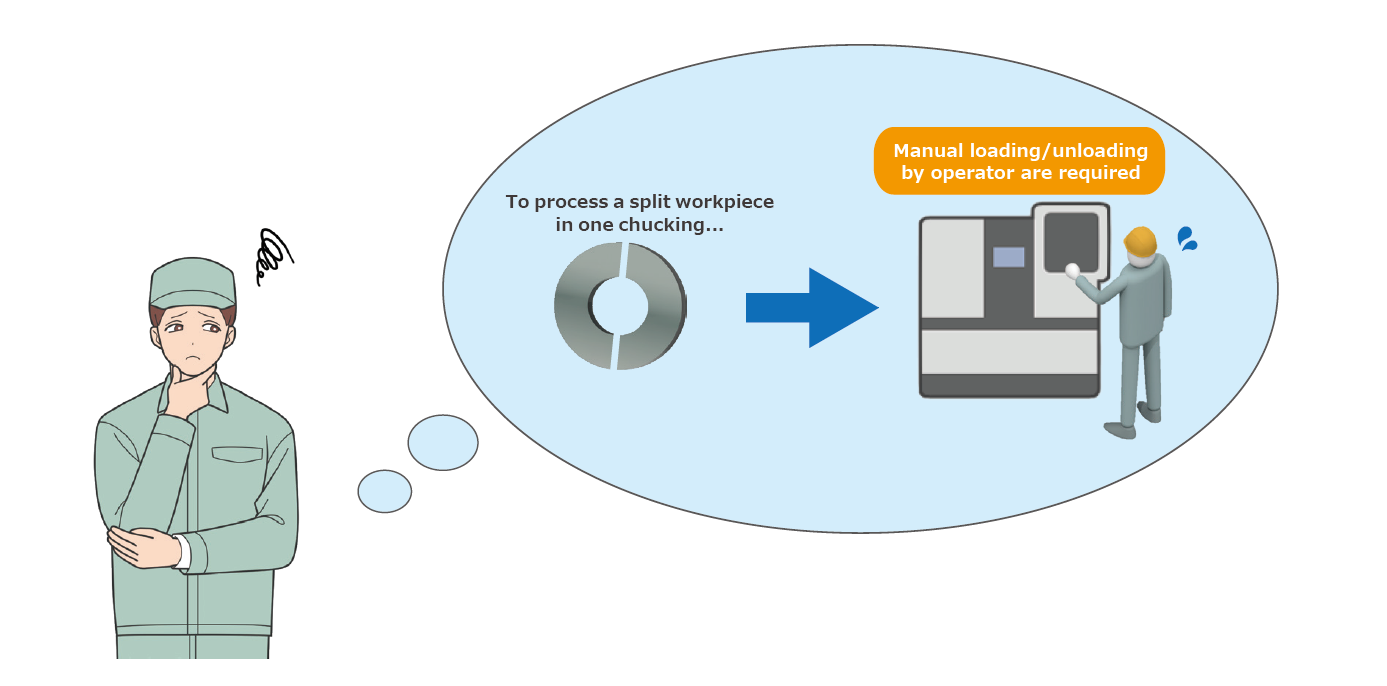

#20 Improving a production line where manual operation was thought to be necessary!

This is an example of Muratec’s unique technological approach with wide-ranging design experts!

Dec 26, 2024

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

❄Season’s Greetings❄

Dec 26, 2024

#20 Improving a production line where manual operation was thought to be necessary!

This is an example of Muratec’s unique technological approach with wide-ranging design experts!

Dec 26, 2024

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

| Company Name |

Murata Machinery, Ltd. Japanese Name : Murata Kikai Kabushiki Kaisha |

|---|---|

| Established | July 1935 |

| Main office | 136, Takeda-Mukaishiro-cho, Fushimi-ku, Kyoto 612-8418 Japan |

| Branch office (Japan) | Tokyo, Osaka, Nagoya |

| Factories (Japan) | Inuyama, Kaga, Ryuo, Oita, Ise, Gifu |

| President | Daisuke Murata |

| Products |

Textile Machinery, Machine Tools, Sheet Metal Machinery, Automated Systems, Clean FA Systems, Communication Equipment |

| Capital | JPY 900 million |

| Sales |

Consolidated: 391,800 million yen Non-Consolidated: 304,300 million yen (as of March 31, 2022) |

| Employees | 3700 [Group; 8100 ](as of April, 2022) |