#006

"We want to improve the long non-productive time and low productivity!"

⚡Points of the problem faced by the customer⚡

1. Non-productive time is long because workers transfer workpieces between machines.

2. A lot of human intervention involved in each process causes inconsistent production volume and quality among workers.

3. The large floor space occupied by many machines imposes various restrictions on work activities.

💡What we can do for the customer💡

Process integration by replacing 5 machines (for 5 processes) with 1 machine MT200 (2 processes)!

Achieves shorter cycle time, consistent quality and production volume, and space saving!

Our proposals to solve the above customer’s problems are as follows:

📝Proposals

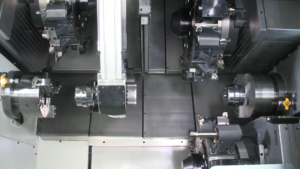

1. Integration of conventional 5 processes, (3 turning, 1 machining, and 1 deburring) into 2 processes by using MT200 (Turning Center) equipped with a gantry loader!

By automating the conventional loading/unloading of workpieces and the transfer of them between machines, we have achieved shorter cycle time and consistent production quality and volume.

2. The process automation with the gantry loader has narrowed down the human intervention spots to only two (one for loading workpieces and the other for collecting finished parts)!

In the past, there were about 15 human intervention spots in total for loading/unloading workpieces, transporting between machines, starting machining programs, and other operations throughout the five processes.

The MT200 allows for reducing the number of intervention points to two, resulting in not only elimination of variations in quality and production volume among operators, but also labor saving.

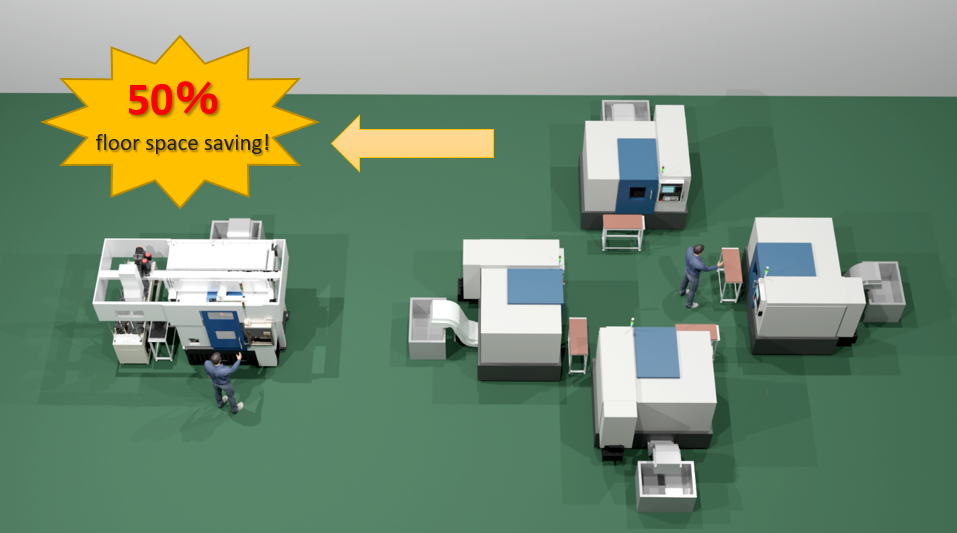

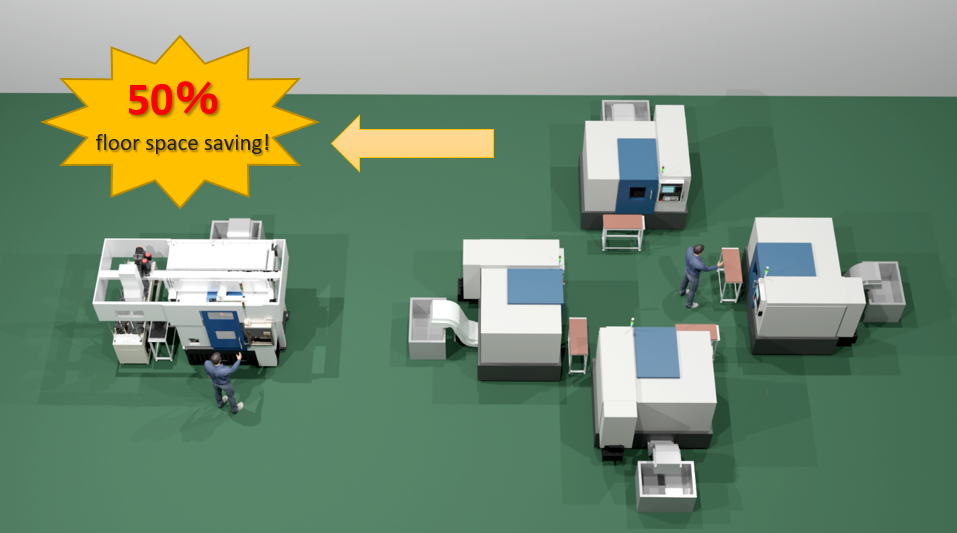

3. About 50% space saving compared to the conventional process!

This system requires only about half the floor space of conventional machines, and has demonstrated capabilities that exceed those of conventional processes, contributing to the great improvement of the customer's production efficiency.

✨Productivity

・Reduced cycle time: With the unnecessary human intervention time eliminated, the overall cycle time has been dramatically reduced.

・Consistent production volume and quality: The automated inter-process transportation has eliminated variations in quality and production volume among workers.

・Space-saving: The floor space necessary for production has been reduced by approximately 50%, with the production capacity and productivity improved.

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

#18 Realizing a compact automated production system by consolidating four manually-operated machines into one machine equipped with a loader!

Feb 29, 2024

⛄Season’s Greetings⛄

Dec 28, 2023

#17 By replacing a long-used single-spindle lathe and robot system with Muratec’s gantry loader system, the productivity per floor space has been significantly improved.

Dec 14, 2023

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

#18 Realizing a compact automated production system by consolidating four manually-operated machines into one machine equipped with a loader!

Feb 29, 2024

| Company Name |

Murata Machinery, Ltd. Japanese Name : Murata Kikai Kabushiki Kaisha |

|---|---|

| Established | July 1935 |

| Main office | 136, Takeda-Mukaishiro-cho, Fushimi-ku, Kyoto 612-8418 Japan |

| Branch office (Japan) | Tokyo, Osaka, Nagoya |

| Factories (Japan) | Inuyama, Kaga, Ryuo, Oita, Ise, Gifu |

| President | Daisuke Murata |

| Products |

Textile Machinery, Machine Tools, Sheet Metal Machinery, Automated Systems, Clean FA Systems, Communication Equipment |

| Capital | JPY 900 million |

| Sales |

Consolidated: 391,800 million yen Non-Consolidated: 304,300 million yen (as of March 31, 2022) |

| Employees | 3700 [Group; 8100 ](as of April, 2022) |