#003

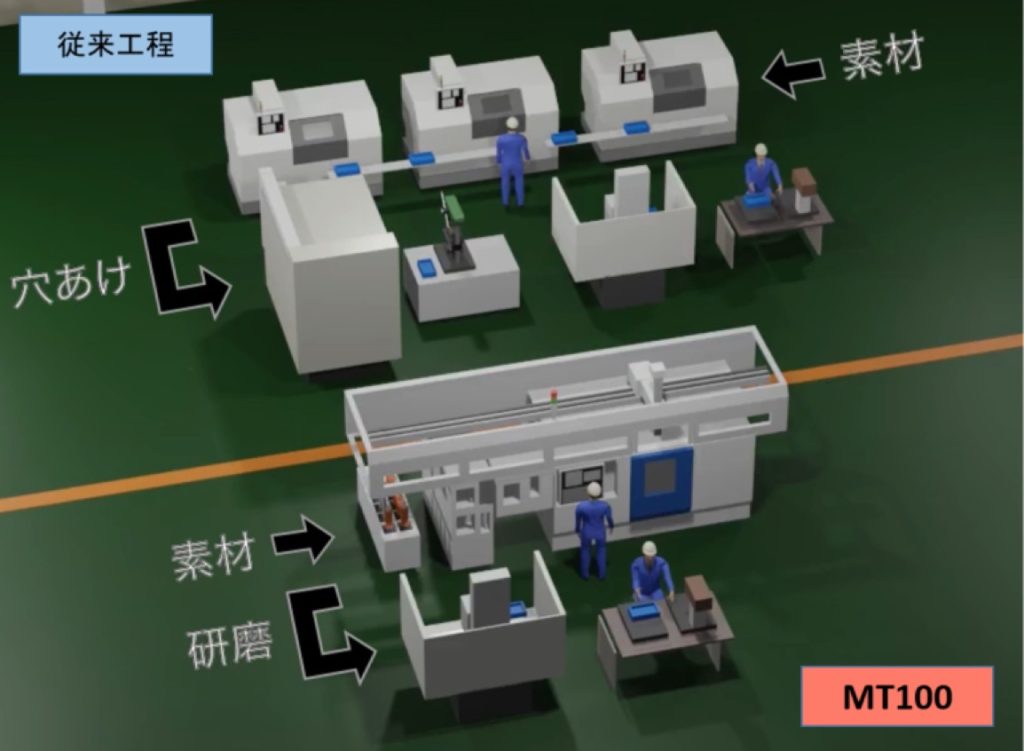

To solve the above challenges that the customer had, we proposed “automatization of production line by introducing our multi-tasking machine”

Our proposals consist of “integration of machining, deburring, and marking processes;” “machining of 4 parts from a single material;” and “creation of machining program by using CAM”.

Our multi-functional MT100 has a live tool function, which enable drilling on the end face of a workpiece, deburring, and marking on the sides of the workpiece. In other words, lathing, machining center (drilling), manual operating tools (deburring) and marking operations that usually require three kinds of machines can be performed in a single machine.

That eliminates variation in production output caused by different skill levels among operators, allowing for stable volume of production.

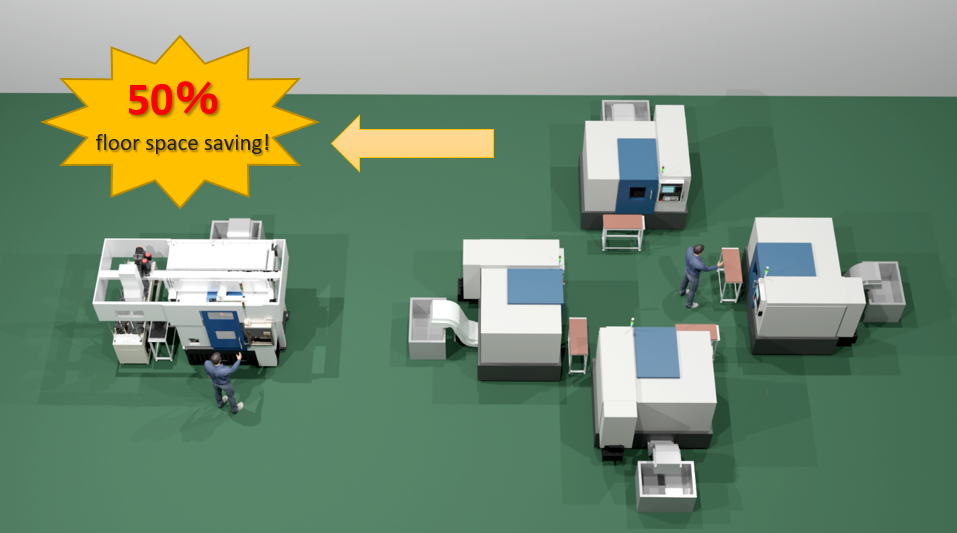

It is now possible to produce multiple finished parts from a bar material instead of Cutting material one by one as conventionally done.

Applying this preset number parts production has also contributed to the material cost saving.

In order to respond to increasingly complicated product shapes and complex operations through process integration, the optimum machining programs can be created with CAM from the data on workpieces, machines, and cutting tools.

In addition, the processing simulation function enables any interference in the machining area, as well as cycle time, to be checked without using actual equipment.

Therefore, careful study can be made for new workpieces without stopping the on-going operations of the equipment, leading to shorter start-up times for machining new workpieces.

We are determined to work seriously on the customer’s issues, propose various ideas, and clear the hurdles in cooperation with the customer.

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

#18 Realizing a compact automated production system by consolidating four manually-operated machines into one machine equipped with a loader!

Feb 29, 2024

⛄Season’s Greetings⛄

Dec 28, 2023

#17 By replacing a long-used single-spindle lathe and robot system with Muratec’s gantry loader system, the productivity per floor space has been significantly improved.

Dec 14, 2023

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

#18 Realizing a compact automated production system by consolidating four manually-operated machines into one machine equipped with a loader!

Feb 29, 2024

| Company Name |

Murata Machinery, Ltd. Japanese Name : Murata Kikai Kabushiki Kaisha |

|---|---|

| Established | July 1935 |

| Main office | 136, Takeda-Mukaishiro-cho, Fushimi-ku, Kyoto 612-8418 Japan |

| Branch office (Japan) | Tokyo, Osaka, Nagoya |

| Factories (Japan) | Inuyama, Kaga, Ryuo, Oita, Ise, Gifu |

| President | Daisuke Murata |

| Products |

Textile Machinery, Machine Tools, Sheet Metal Machinery, Automated Systems, Clean FA Systems, Communication Equipment |

| Capital | JPY 900 million |

| Sales |

Consolidated: 391,800 million yen Non-Consolidated: 304,300 million yen (as of March 31, 2022) |

| Employees | 3700 [Group; 8100 ](as of April, 2022) |