#13

“Although we have to handle high-mix production, the conventional system required changeover time, which lowered the overall production efficiency. Therefore, we would like to increase the productivity by eliminating the changeover as much as possible.”

⚡Points of the problem faced by the customer⚡

[1] The customer wanted to eliminate the changeover time (20 minutes) per part type on the infeed unit (parts feeder).

[2] They also wanted to eliminate small adjustments when changing parts on the parts feeder.

[3] Although the parts feeder was manufactured by a

nthird party vendor, the customer wanted to use a peripheral system supplied from a single manufacturer, from the maintenance stand point.

💡What we can do for the customer💡

- Proposing a infeed unit that can handle multiple types of workpieces without changeover!

Achieving a 5% increase of the equipment operating rate and saving more operation time by using a stocker not requiring changeover !

- The customer’s system was operated 21 hours per day with 3 shifts for 3 times of changeover per day, resulting in a total of 60 minutes of machine down time.

By eliminating the 60 minute changeover time and keeping the system running, the system operating rate can be improved by 5%.

In addition, by allocating the man-hours for changeover to other processes, operators can have their time more and they can put their effort on other work.

‐ When listening to the customer’s issue, we found that the greatest point is how to eliminate the “changeover time” that hinders the productivity.

Therefore, we proposed to develop a system consisting of an muratec standard stocker and a specially designed pallet jig at a reasonable price to solve the issue.

Sales and SE departments of Muratec always offer the best proposal for individual customers after grasping their issues at the inquiry stage.

✨Higher Productivity

- Productivity has been greatly improved by adopting high-mix production without changeover.

- The on-site operational efficiency has also been much improved by eliminating the time for parts changeover.

- Compared to the conventional parts feeder system, the acceptable stock quantity has increased, allowing for automatic operation for more than 4 hours, that leads to further productivity improvement.

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

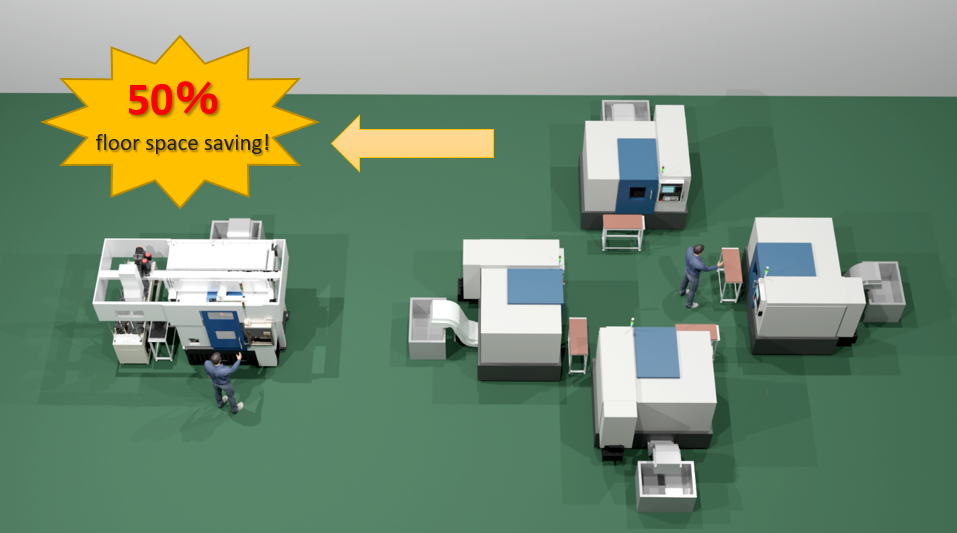

#18 Realizing a compact automated production system by consolidating four manually-operated machines into one machine equipped with a loader!

Feb 29, 2024

⛄Season’s Greetings⛄

Dec 28, 2023

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

| Company Name |

Murata Machinery, Ltd. Japanese Name : Murata Kikai Kabushiki Kaisha |

|---|---|

| Established | July 1935 |

| Main office | 136, Takeda-Mukaishiro-cho, Fushimi-ku, Kyoto 612-8418 Japan |

| Branch office (Japan) | Tokyo, Osaka, Nagoya |

| Factories (Japan) | Inuyama, Kaga, Ryuo, Oita, Ise, Gifu |

| President | Daisuke Murata |

| Products |

Textile Machinery, Machine Tools, Sheet Metal Machinery, Automated Systems, Clean FA Systems, Communication Equipment |

| Capital | JPY 900 million |

| Sales |

Consolidated: 391,800 million yen Non-Consolidated: 304,300 million yen (as of March 31, 2022) |

| Employees | 3700 [Group; 8100 ](as of April, 2022) |