#12

"In introducing automatic production line, we want to automate as many processes as possible by using a gantry loader (hereafter simply referred to as Loader) to improve production efficiency."

⚡Points of the problem faced by the customer⚡

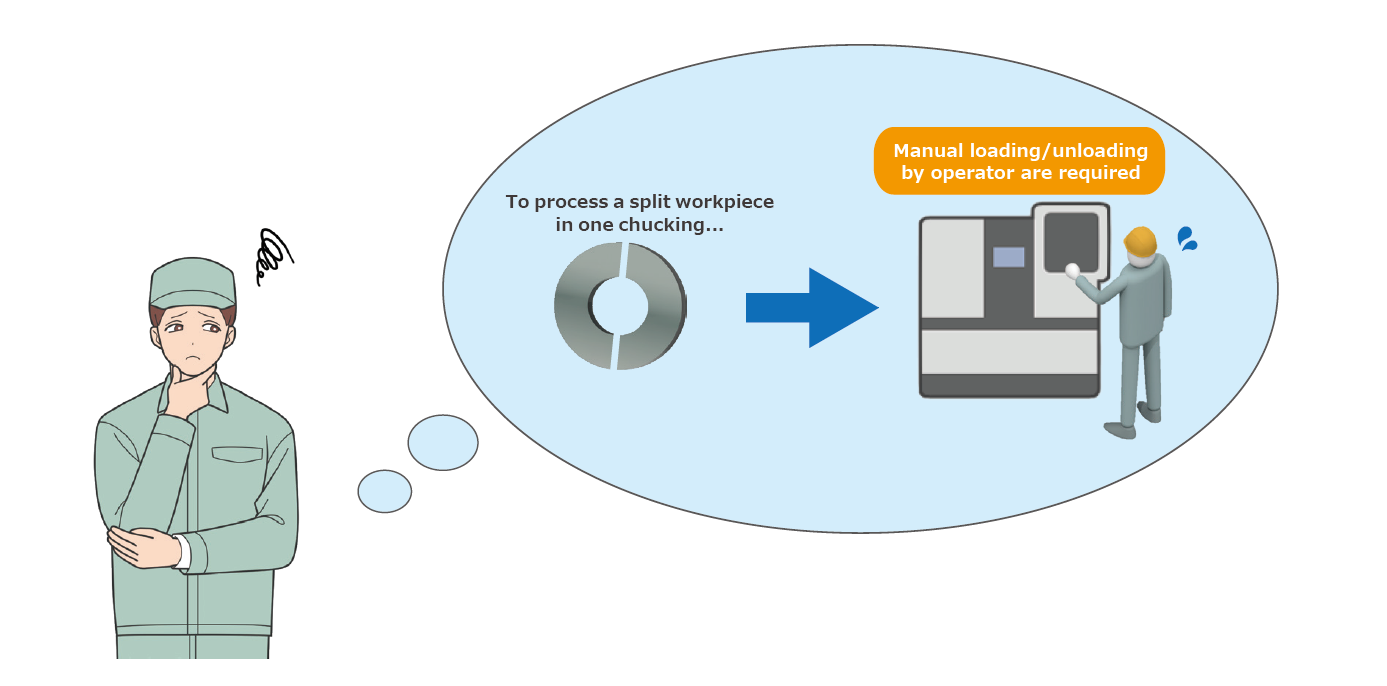

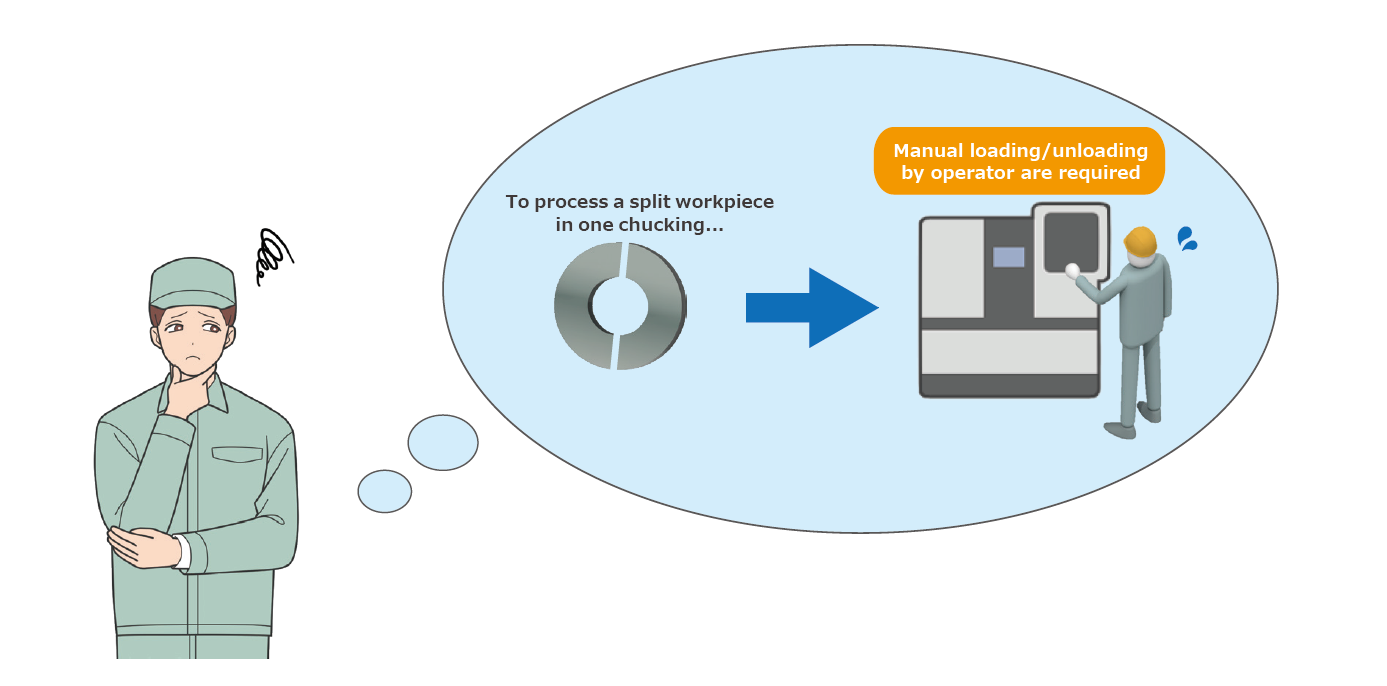

[1] First, the customer wanted to automate machining process and eliminate variations in production volume caused by workers.

[2] Also, they wanted to automate the cleaning and inspection processes after machining.

[3] Since the clearance between the chuck and the workpiece was very small, there was concern about whether the Loader could precisely attach and detach the workpieces.

💡What we can do for the customer💡

・ The production efficiency has been greatly improved by automating all processes with the Loader!

Our proposals to solve the customer's problems are as follows.

📝Proposals

・ In addition to the machining process, the customer's cleaning equipment and inspection equipment are also arranged in the transport area, where the Loader is used to automate the entire process.

Before that, we adjusted the signal exchange between the cleaning equipment and inspection equipment to enable a smooth start-up of the production line at the time of delivery.

・ Although the clearance between the precision mandrel chuck and the inner diameter of the workpiece is very small, the Loader has enabled accurate automatic loading and unloading of workpieces.

At the time of business negotiations, we conducted verification of the Loader's loading/unloading performance at our company. For more smooth chucking and unchucking operations, we changed the shape of the chuck side. Also, after repeatedly verifying the movement coordinates on the gantry loader side, the anxiety about automatic attachment and detachment has been eliminated.

✨Higher Productivity

・ Through this automation, variations in production volume have been improved.

・ By automating the entire process, the number of workers involved in the process can be reduced from four to one.

・ The three workers who left the previous process are now working in other processes, also contributing to improving the productivity of those proc

❄Season’s Greetings❄

Dec 26, 2024

#20 Improving a production line where manual operation was thought to be necessary!

This is an example of Muratec’s unique technological approach with wide-ranging design experts!

Dec 26, 2024

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

❄Season’s Greetings❄

Dec 26, 2024

#20 Improving a production line where manual operation was thought to be necessary!

This is an example of Muratec’s unique technological approach with wide-ranging design experts!

Dec 26, 2024

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

| Company Name |

Murata Machinery, Ltd. Japanese Name : Murata Kikai Kabushiki Kaisha |

|---|---|

| Established | July 1935 |

| Main office | 136, Takeda-Mukaishiro-cho, Fushimi-ku, Kyoto 612-8418 Japan |

| Branch office (Japan) | Tokyo, Osaka, Nagoya |

| Factories (Japan) | Inuyama, Kaga, Ryuo, Oita, Ise, Gifu |

| President | Daisuke Murata |

| Products |

Textile Machinery, Machine Tools, Sheet Metal Machinery, Automated Systems, Clean FA Systems, Communication Equipment |

| Capital | JPY 900 million |

| Sales |

Consolidated: 391,800 million yen Non-Consolidated: 304,300 million yen (as of March 31, 2022) |

| Employees | 3700 [Group; 8100 ](as of April, 2022) |