#010

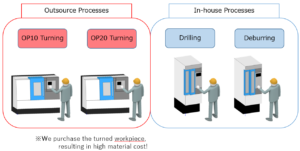

"Since we have no equipment for turning operations, we purchase the turned workpiece, resulting in high material cost."

"The cost reduction through process improvement is not easy, making it difficult to secure profits."

⚡Points of the problem faced by the customer⚡

1. Even if we try to perform all processes in-house, there is no more space to install new processing equipment, and there are no operators.

2. Currently, the purchased materials are subjected to two processes, drilling and deburring, but each process is labor intensive, using a manual machine.

💡What we can do for the customer💡

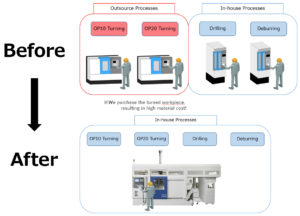

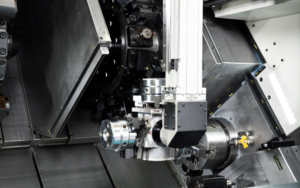

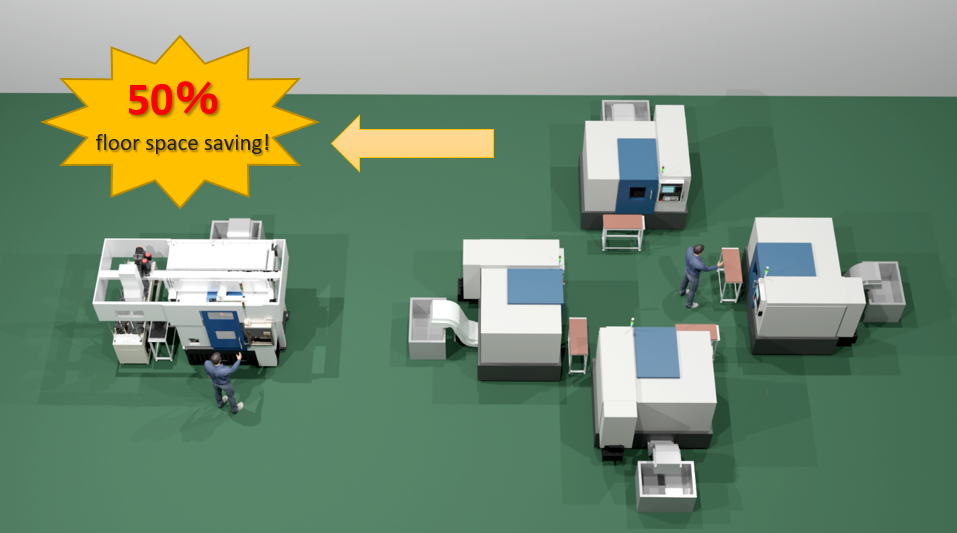

Equipped with a gantry loader, a single unit of the multi-tasking turning machine MT200 enables all machining processes to be performed, and the total number of operators can be reduced through this automation!

Our proposals to solve the customer’s problems are as follows.

📝Proposals

1. In order to increase the added value of the customer's product, we proposed incorporating all the processes, including the turning process, which had been outsourced previously, into one machine. As a result, significant reduction in material cost has been achieved.

In addition, it takes up less space than the previous production equipment used for two processes. Moreover, with all the processes integrated into one machine, product management has become much easier.

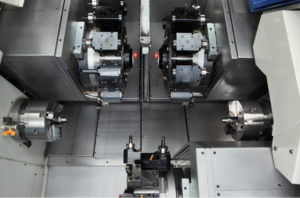

For multi-process machining operations, which require a large number of cutting tools, the three-turret type design allows up to 54 cutting tools to be mounted on one machine.

2. Conventionally, each process was performed with a manual machine, taking a lot of manpower. By using our gantry loader with the machine, however, unmanned operation is now possible for a certain period of time.

We have a wide range of peripheral equipment such as loading/unloading devices and automatic gauge unit, so we can propose the machine specifications that can most suitably meet the customer's request.

✨Higher Productivity

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

#18 Realizing a compact automated production system by consolidating four manually-operated machines into one machine equipped with a loader!

Feb 29, 2024

⛄Season’s Greetings⛄

Dec 28, 2023

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

| Company Name |

Murata Machinery, Ltd. Japanese Name : Murata Kikai Kabushiki Kaisha |

|---|---|

| Established | July 1935 |

| Main office | 136, Takeda-Mukaishiro-cho, Fushimi-ku, Kyoto 612-8418 Japan |

| Branch office (Japan) | Tokyo, Osaka, Nagoya |

| Factories (Japan) | Inuyama, Kaga, Ryuo, Oita, Ise, Gifu |

| President | Daisuke Murata |

| Products |

Textile Machinery, Machine Tools, Sheet Metal Machinery, Automated Systems, Clean FA Systems, Communication Equipment |

| Capital | JPY 900 million |

| Sales |

Consolidated: 391,800 million yen Non-Consolidated: 304,300 million yen (as of March 31, 2022) |

| Employees | 3700 [Group; 8100 ](as of April, 2022) |