#009

"Complicated operations require different machine tools to be used according to the shape of materials."

⚡Points of the problem faced by the customer⚡

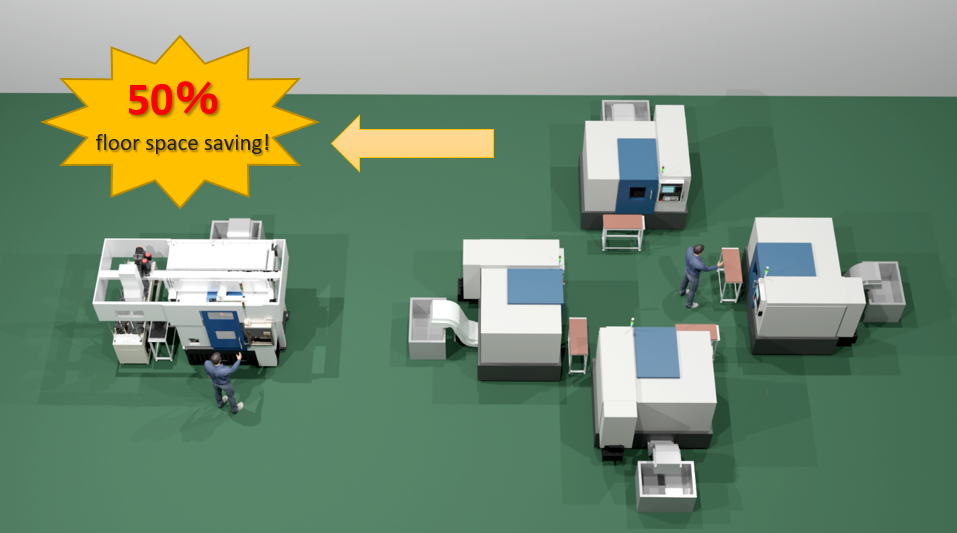

1. Workpieces of 65mm or less were processed by a bar machine, while larger ones were made from cut materials by using two units of single-spindle lathes, requiring multiple operators.

2. Due to the high hurdles to implementing automation, labor saving on the production line did not proceed as expected.

💡What we can do for the customer💡

A turning center equipped with a gantry loader, bar feeder, and stocker has achieved efficient automation, while reducing the number of machine tools.

Our proposals to solve the customer’s problems are as follows.

📝Proposals

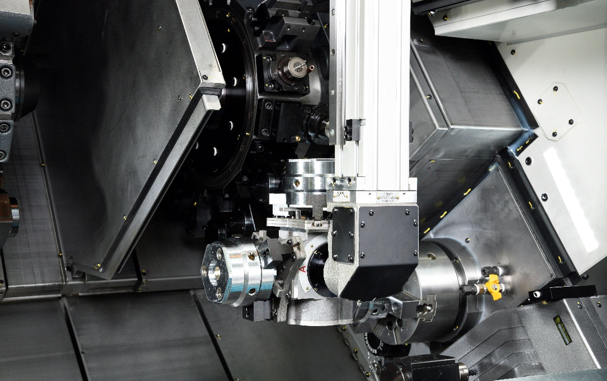

[1] One turning center handles both bar materials and cut materials!

For bar materials, a bar feeder is installed on the left side of the MT200, while a stocker is incorporated on the right side for cut materials.

As a result, both bar materials and cut materials can be processed with one machine.

In addition, if the 3-turret type is chosen, the machine can be equipped with a maximum of 54 cutting tools.

[2] Mounting a gantry loader on the machine allows for easy automation!

🔵Bar material machining cycle

Bar feeder ➡ Left axis (OP10) ➡ Right axis (OP20) ➡ Gantry loader picking up finished parts ➡ Stocker

🔵Cut material machining cycle

Stocker ➡Left axis (OP10) ➡ Right axis (OP20) ➡Gantry loader picking up finished parts ➡ Stocker (return)

In this way, the process of loading materials and the process of unloading finished parts have been automated.

✨Higher Productivity

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

#18 Realizing a compact automated production system by consolidating four manually-operated machines into one machine equipped with a loader!

Feb 29, 2024

⛄Season’s Greetings⛄

Dec 28, 2023

#17 By replacing a long-used single-spindle lathe and robot system with Muratec’s gantry loader system, the productivity per floor space has been significantly improved.

Dec 14, 2023

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

#18 Realizing a compact automated production system by consolidating four manually-operated machines into one machine equipped with a loader!

Feb 29, 2024

| Company Name |

Murata Machinery, Ltd. Japanese Name : Murata Kikai Kabushiki Kaisha |

|---|---|

| Established | July 1935 |

| Main office | 136, Takeda-Mukaishiro-cho, Fushimi-ku, Kyoto 612-8418 Japan |

| Branch office (Japan) | Tokyo, Osaka, Nagoya |

| Factories (Japan) | Inuyama, Kaga, Ryuo, Oita, Ise, Gifu |

| President | Daisuke Murata |

| Products |

Textile Machinery, Machine Tools, Sheet Metal Machinery, Automated Systems, Clean FA Systems, Communication Equipment |

| Capital | JPY 900 million |

| Sales |

Consolidated: 391,800 million yen Non-Consolidated: 304,300 million yen (as of March 31, 2022) |

| Employees | 3700 [Group; 8100 ](as of April, 2022) |