#008

“There are many machines that need to be replaced due to aging, but we want to reduce the number of machines to be reinvested while maintaining the current production volume."

⚡Points of the problem faced by the customer⚡

1. The customer wants to reduce the cycle time in order to reduce the number of machines to be invested.

2. Since both the current production volume and the number of machines to be reinvested are large, they want to use this opportunity to automate and optimize the production line.

3. If the machining time reduction is achieved, a “high-speed” transport device will be required.

💡What we can do for the customer💡

We verified the reduced cycle time through trial cutting, and also realized short- cycle high-speed transfer by using our Twin Gantry Loader!

Our proposals to solve the customer’s problems are as follows.

📝Proposals

1. Trial cutting was carried out at our factory, where the cycle time was actually reduced!

Specifically, we analyzed and verified the conventional machining program in cooperation with the customer.

As a result, we reduced both cutting time and non-cutting time while satisfying the accuracy requirements, and finally optimized the machining program.

2. In addition to the reduction of cycle time, efficient high-speed transfer has been realized by the Twin Gantry Loader!

For example, our twin-spindle turning center MW100Ⅱ equipped with the twin gantry loader can achieve a high-speed transfer cycle of as fast as 12 seconds (including loading and unloading time of about 6 seconds).

Therefore, if the cycle time is 12 seconds or longer (including about 6 seconds for loading and unloading), the machining cycle can be performed very efficiently without machining waiting for the loader.

✨Higher Productivity

❄Season’s Greetings❄

Dec 26, 2024

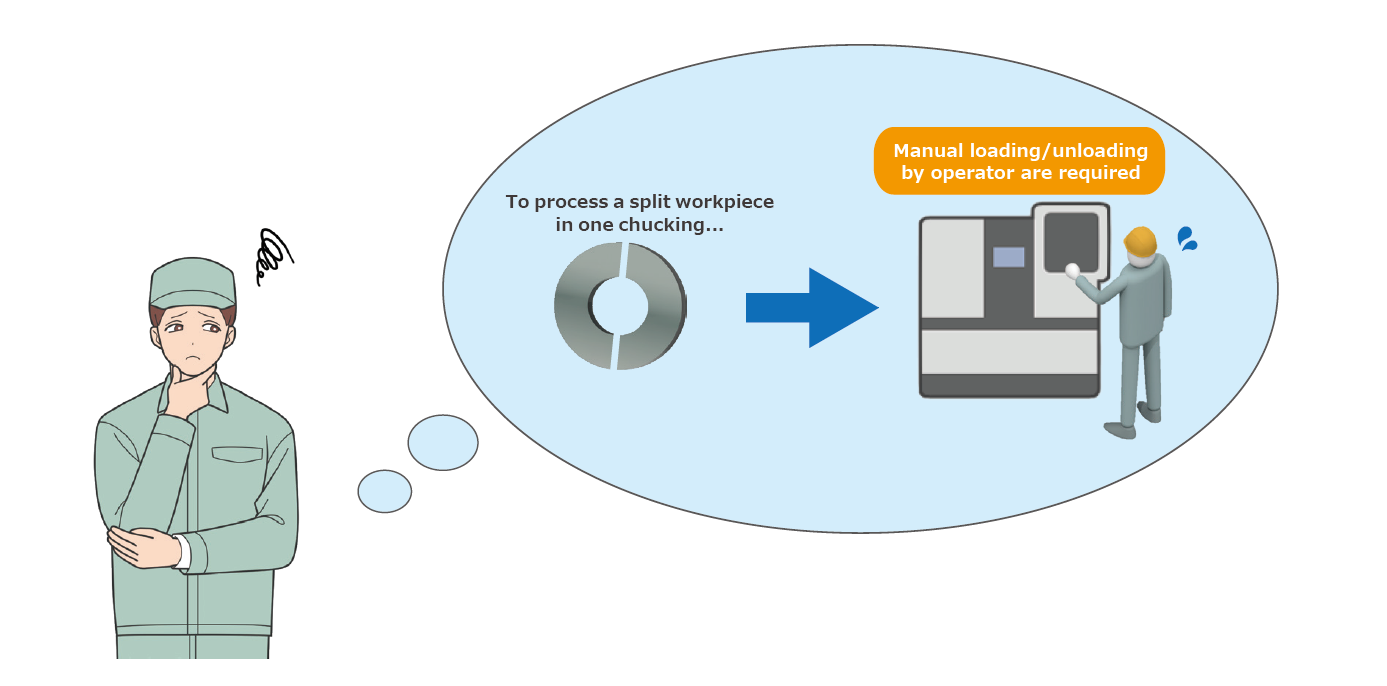

#20 Improving a production line where manual operation was thought to be necessary!

This is an example of Muratec’s unique technological approach with wide-ranging design experts!

Dec 26, 2024

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

❄Season’s Greetings❄

Dec 26, 2024

#20 Improving a production line where manual operation was thought to be necessary!

This is an example of Muratec’s unique technological approach with wide-ranging design experts!

Dec 26, 2024

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

| Company Name |

Murata Machinery, Ltd. Japanese Name : Murata Kikai Kabushiki Kaisha |

|---|---|

| Established | July 1935 |

| Main office | 136, Takeda-Mukaishiro-cho, Fushimi-ku, Kyoto 612-8418 Japan |

| Branch office (Japan) | Tokyo, Osaka, Nagoya |

| Factories (Japan) | Inuyama, Kaga, Ryuo, Oita, Ise, Gifu |

| President | Daisuke Murata |

| Products |

Textile Machinery, Machine Tools, Sheet Metal Machinery, Automated Systems, Clean FA Systems, Communication Equipment |

| Capital | JPY 900 million |

| Sales |

Consolidated: 391,800 million yen Non-Consolidated: 304,300 million yen (as of March 31, 2022) |

| Employees | 3700 [Group; 8100 ](as of April, 2022) |