#007

"It takes a lot of time and money to change the flow direction of workpieces after machine installation."

⚡Points of the problem faced by the customer⚡

・Remodeling the system cannot be done by the customer’s engineers, so it is necessary to request the manufacturer.

・Some transfer equipment makes it difficult to change the installation location, requiring major modifications or new arrangements.

💡What we can do for the customer💡

This enables customer’s engineers to easily make changes after machine installation without relying on the manufacturer!

Our proposals to solve the customer’s problems are as follows.

📝Proposals

1.All the customer has to do is simply call the loader program prepared in advance!

The loader program is created in advance, with the altered flow directions or the replacement of transfer equipment taken into account, and the operation is checked before shipment of the system!

2.No need to make major modifications or new arrangements for transfer equipment! Allowing for flexible line changes!

For example, simply by changing the electrical control panel position of our existing stocker and/or preparing a long cable to the machine, it is possible to install the transfer unit on either the left or right side of the machine.

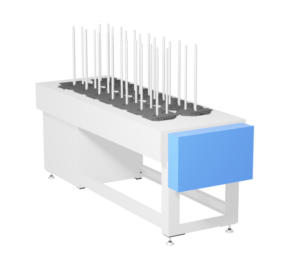

↓Existing Stocker

↓ Special Stocker

(The blue box is electrical control panel)

✨Automation

❄Season’s Greetings❄

Dec 26, 2024

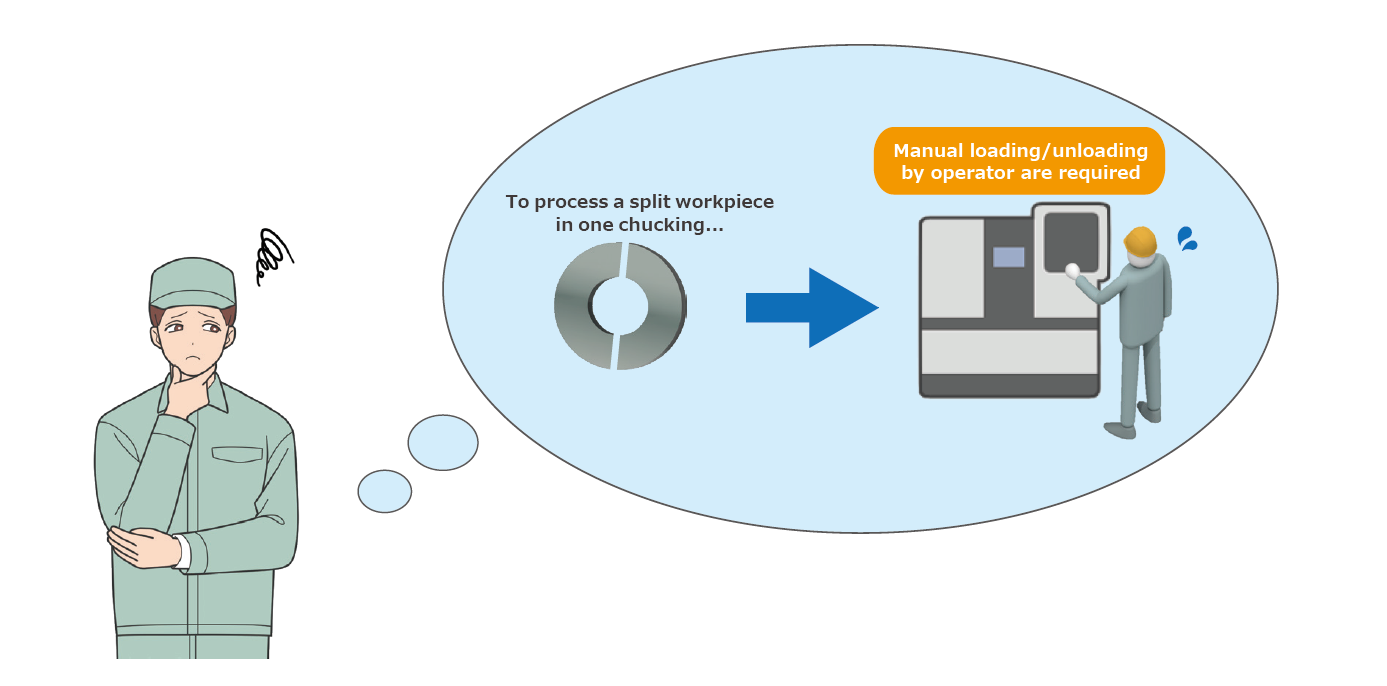

#20 Improving a production line where manual operation was thought to be necessary!

This is an example of Muratec’s unique technological approach with wide-ranging design experts!

Dec 26, 2024

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

❄Season’s Greetings❄

Dec 26, 2024

#20 Improving a production line where manual operation was thought to be necessary!

This is an example of Muratec’s unique technological approach with wide-ranging design experts!

Dec 26, 2024

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

| Company Name |

Murata Machinery, Ltd. Japanese Name : Murata Kikai Kabushiki Kaisha |

|---|---|

| Established | July 1935 |

| Main office | 136, Takeda-Mukaishiro-cho, Fushimi-ku, Kyoto 612-8418 Japan |

| Branch office (Japan) | Tokyo, Osaka, Nagoya |

| Factories (Japan) | Inuyama, Kaga, Ryuo, Oita, Ise, Gifu |

| President | Daisuke Murata |

| Products |

Textile Machinery, Machine Tools, Sheet Metal Machinery, Automated Systems, Clean FA Systems, Communication Equipment |

| Capital | JPY 900 million |

| Sales |

Consolidated: 391,800 million yen Non-Consolidated: 304,300 million yen (as of March 31, 2022) |

| Employees | 3700 [Group; 8100 ](as of April, 2022) |