#002

“We want to build a ‘flexible production line’ that not only reduces the defect rate, but also achieves stable operation and total cost reduction.”

The customer who consulted with us and requested as above had the following three issues when performing production with manually operated lines using five machine tools.

1.It is desired to shorten the cycle time, improve the line operating rate, and reduce labor costs.

2.In the manual loading productions separated for individual processes, defects are likely to occur between the processes.

3.It is desired to quickly respond to production fluctuations through stand-alone production system instead of the conventional line-type production.

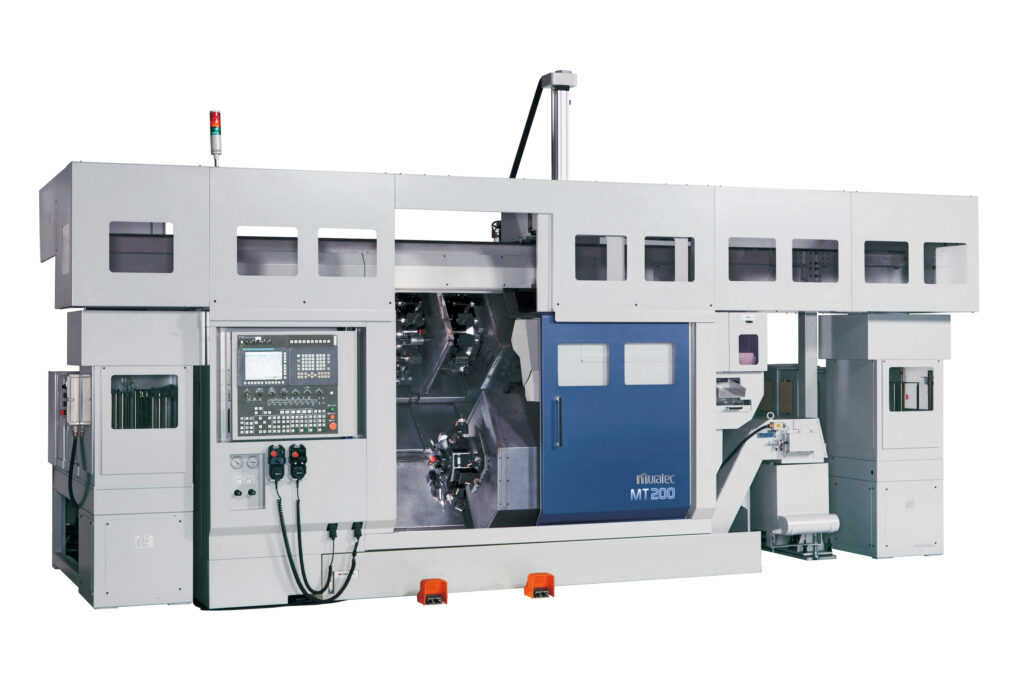

Installing the “Twin Opposing Spindle Machines ‘MT200,’” equipped with 3 turrets, Y-axis, C-axis and live function, to achieve the “defective rate reduction,” “stable operation” and “cost saving”!

Our proposals to solve the customer’s issues mentioned above are as follows:

💡Our Proposals and Effects💡

(1) “Process Integration” for shortening the cycle time, increasing the line operating rate, and saving the labor costs!

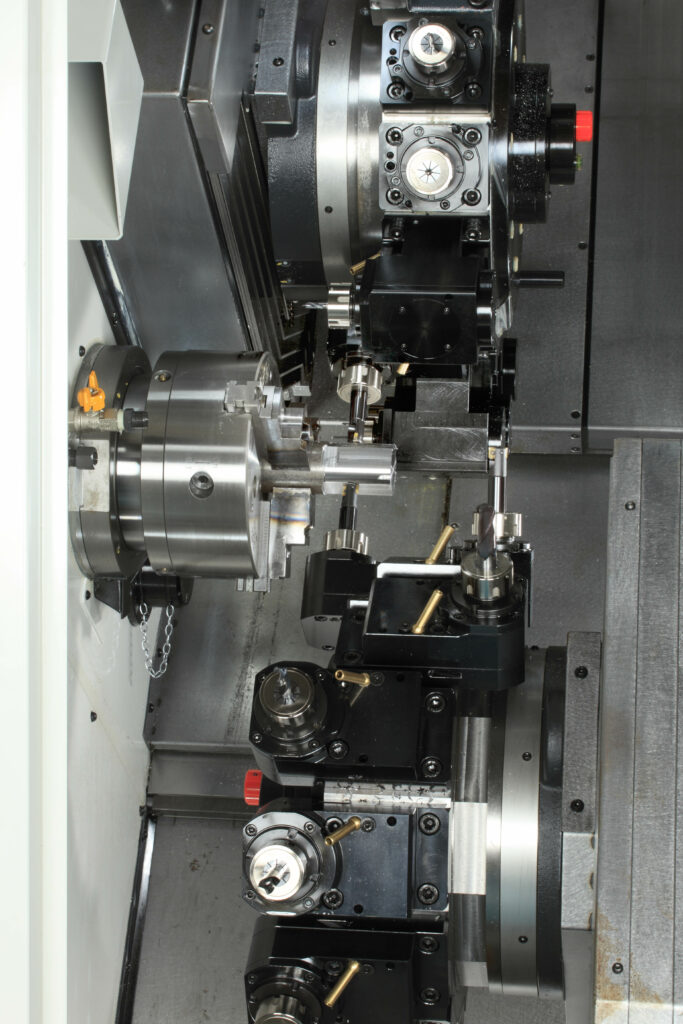

The cutting time has been significantly reduced with the use of the three turrets.

The simultaneous cutting by using the upper and lower turrets are carried out during not only lathing but also milling operations.

Also, while machining is performed with one turret, indexing and approaching are performed with the other turret, resulting in great reduction of wasted idle time (non-cutting time).

In addition, by integrating the processes, the work-in-process has been eliminated and the operating rate has been greatly improved. At the same time, multiple machines can be controlled by one operator, resulting in labor cost saving.

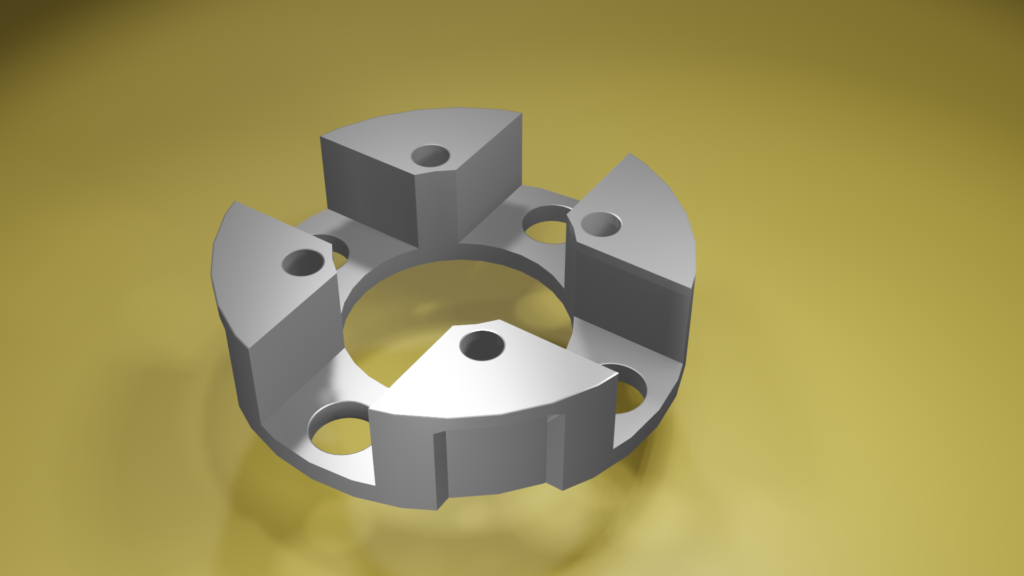

By replacing the conventional 2-jaw chuck, which was a bottleneck to improve the machining conditions, with a 4-jaw chuck, it has become possible to improve the machining conditions and shorten the cycle time with the machining accuracy maintained.

(2) Automatic operations with 3 turrets and gantry loader for reducing defects that occurred between processes!

Conventionally, the customer divided process operations as follows: “lathing ⇒ drilling ⇒ lathing ⇒ drilling ⇒ deburring,” and performed manual loading and unloading at each process.

In such multiple processes, which require many times of workpiece loading and unloading, there is a high possibility of causing scratches on workpieces and inter-process defects.

By integrating those five process operations, including the deburring, into our “MT200” and building an automated line with the gantry loader, it has become possible to significantly reduce such inter-process defects, chucking scratches, etc.

In addition, by optimizing the NC programs, the time required for deburring, which has little added value, has also been greatly reduced.

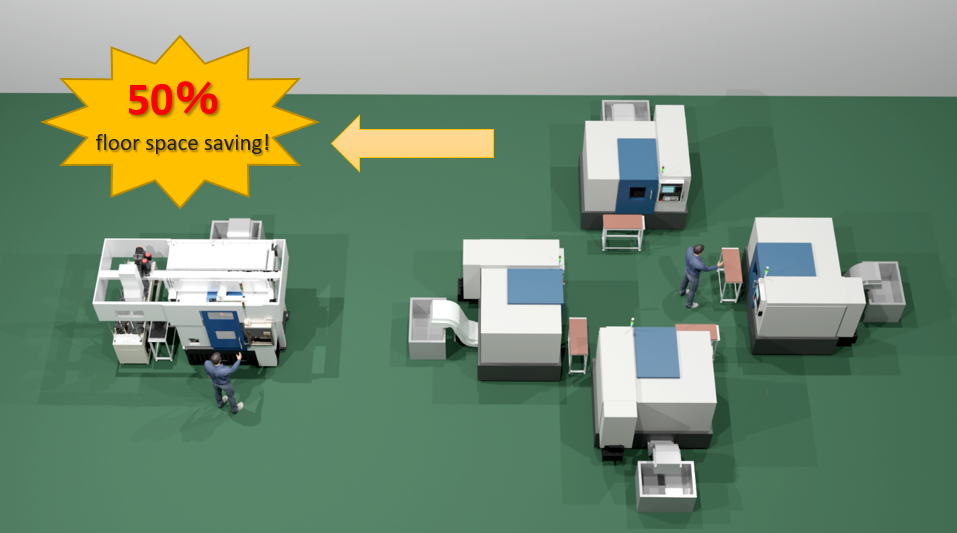

(3) Multi-tasking machine “MT200” for enabling flexible production and minimum setup changes!

As mentioned above, our “MT200” is a multi-functional machine not only equipped with 3 turrets, but also performing even deburring operation.

By installing two or more units of such stand-alone combined processing machines, it has become possible to quickly respond to production fluctuations.

Frequent small increases in production volume can be addressed by increasing the number of the same machines as required, while production cuts also can be responded to simply by reducing the number of machines, and the reduced machines can be used for production of other products.

Through the above proposals [1] to [3], we have provided our customers with the ideal production method that can achieve "total cost reduction."

We are determined to work seriously on the customer’s issues, propose various ideas, and clear the hurdles in cooperation with the customer.

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

#18 Realizing a compact automated production system by consolidating four manually-operated machines into one machine equipped with a loader!

Feb 29, 2024

⛄Season’s Greetings⛄

Dec 28, 2023

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

| Company Name |

Murata Machinery, Ltd. Japanese Name : Murata Kikai Kabushiki Kaisha |

|---|---|

| Established | July 1935 |

| Main office | 136, Takeda-Mukaishiro-cho, Fushimi-ku, Kyoto 612-8418 Japan |

| Branch office (Japan) | Tokyo, Osaka, Nagoya |

| Factories (Japan) | Inuyama, Kaga, Ryuo, Oita, Ise, Gifu |

| President | Daisuke Murata |

| Products |

Textile Machinery, Machine Tools, Sheet Metal Machinery, Automated Systems, Clean FA Systems, Communication Equipment |

| Capital | JPY 900 million |

| Sales |

Consolidated: 391,800 million yen Non-Consolidated: 304,300 million yen (as of March 31, 2022) |

| Employees | 3700 [Group; 8100 ](as of April, 2022) |