#18

“We would like to introduce an automated production line by renewing four very old machines, but purchasing four automated machines would be over budget.”

⚡Points of the problem faced by the customer⚡

(1) The four manually operated machines were severely getting older and were subject to renewal, but it was difficult to replace the four old machines with new ones at once in terms of budget.

(2)When renewing the old machines, the customer wanted to “increase worker’s productivity” by not simply replacing the old manually-operated machines, but by automating the production method.

💡What we can do for the customer💡

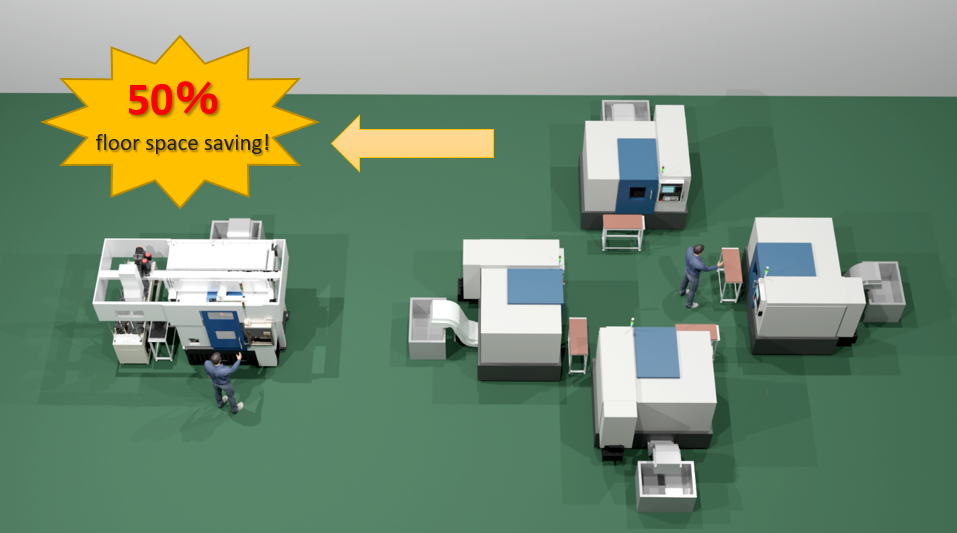

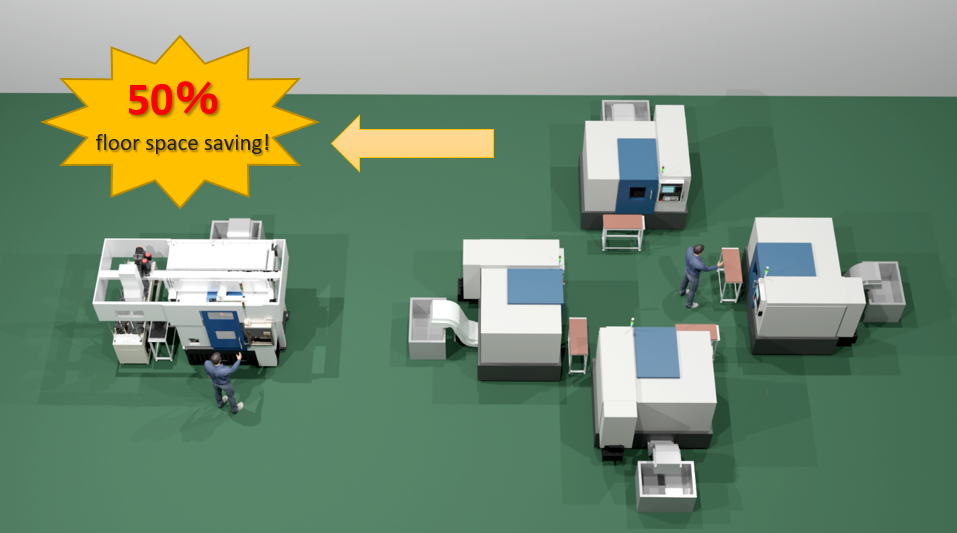

Process integration with one machine equipped with a flexible gantry loader and compact turnaround unit to perform two processes with the machine! That has realized a space-saving and efficient production!

📝Proposals

- First, we examined the customer’s four separate machining processes to integrate them into two processes.

For that purpose, we proposed redesigning the shape of the spindle jaw so that both the 1st and 2nd processes can be performed with the same jaw.

- Then, we proposed installation of a compact turnaround unit, which has many proven track records at Muratec, outside the machine.

This was because the turnaround operation performed outside the machine could shorten the loading time for changing workpieces as much as possible, greatly increasing production efficiency.

✨Higher Productivity

- By consolidating the previous machining processes into one machine and automating the operation with the loader, now the operators need to do is check quality and supply workpieces.

⇒ As a result, they have more time to do other tasks, and the worker’s productivity has been increased accordingly.

#17 By replacing a long-used single-spindle lathe and robot system with Muratec’s gantry loader system, the productivity per floor space has been significantly improved.

The product in the case study introduced here is the CNC Shaft Turning Machine 「ML400」.

https://www.muratec.net/mt/products/ml.html

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

#18 Realizing a compact automated production system by consolidating four manually-operated machines into one machine equipped with a loader!

Feb 29, 2024

⛄Season’s Greetings⛄

Dec 28, 2023

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

| Company Name |

Murata Machinery, Ltd. Japanese Name : Murata Kikai Kabushiki Kaisha |

|---|---|

| Established | July 1935 |

| Main office | 136, Takeda-Mukaishiro-cho, Fushimi-ku, Kyoto 612-8418 Japan |

| Branch office (Japan) | Tokyo, Osaka, Nagoya |

| Factories (Japan) | Inuyama, Kaga, Ryuo, Oita, Ise, Gifu |

| President | Daisuke Murata |

| Products |

Textile Machinery, Machine Tools, Sheet Metal Machinery, Automated Systems, Clean FA Systems, Communication Equipment |

| Capital | JPY 900 million |

| Sales |

Consolidated: 391,800 million yen Non-Consolidated: 304,300 million yen (as of March 31, 2022) |

| Employees | 3700 [Group; 8100 ](as of April, 2022) |