#15

“We want to enhance our competitiveness by introducing a more productive production line.”

⚡Points of the problem faced by the customer⚡

[1] Currently, two lathes and one machining center were operated by a worker. Therefore, work efficiency was poor and the operating rate did not increase as expected, causing a concern about lack of the company’s competitiveness.

[2] Since odd-shaped workpiece requires multiple processes, multiple processing machines mentioned above are used. However, this production method indicated poor time balance and took up a large floor space. To enhance the competitiveness, it needs to be automated but the best way to efficiently automate the process for odd-shaped workpieces is unknown.

💡What we can do for the customer💡

Using Muratec’s flexible gantry loader to compactly integrate the current production line! Minimizing human intervention to build a highly productive line!

Our proposals to solve the customer’s problems are as follows.

📝Proposals

- First of all, we started reviewing the conventional machining processes performed by the “2 lathes and 1 machining center.” In order to integrate several machining processes into one machine, we proposed a plan to use an index chuck that allows four surfaces to be machined in one chucking. Although the cycle time per spindle became longer due to the above process integration, the line takt-time has been shortened as much as possible by using the twin-spindle turning machine to perform the same machining operations with two spindles.

- In the automatic production of odd-shaped workpieces, it is generally difficult for the loader to handle the workpieces, but our “twin-jaw chuck loader” enables smooth handling.

- Moreover, for ensuring stable operations, a high-pressure coolant pump has been employed to solve the problem of “chip disposal,” which is one of the biggest impediments to unattended operations.

✨Higher Productivity

- The loader-based production system has allowed for more stable operations than the conventional manual handling line. Errors caused by workers and quality variation due to re-chucking of workpieces between processes have been eliminated, resulting in a significant improvement in productivity.

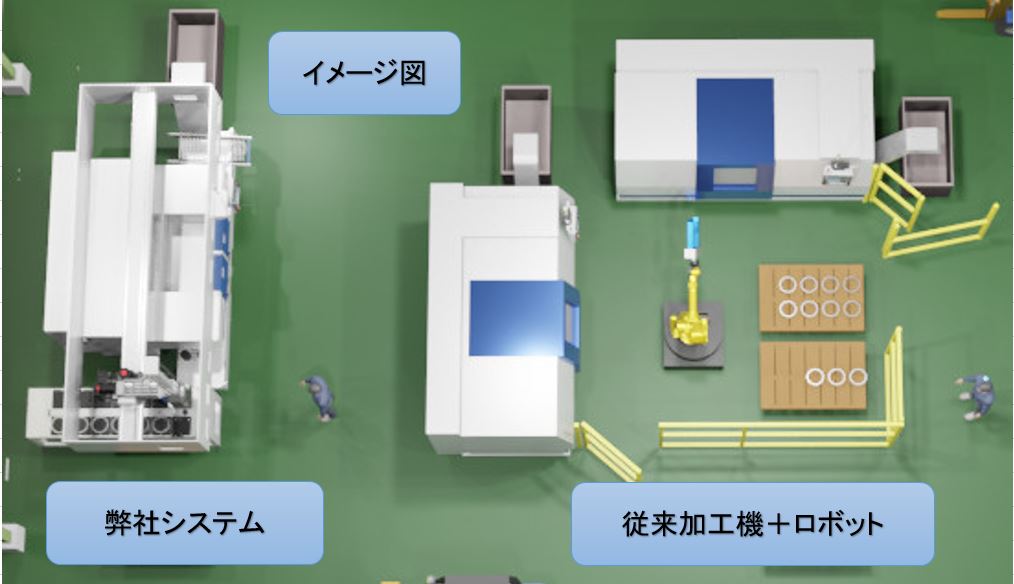

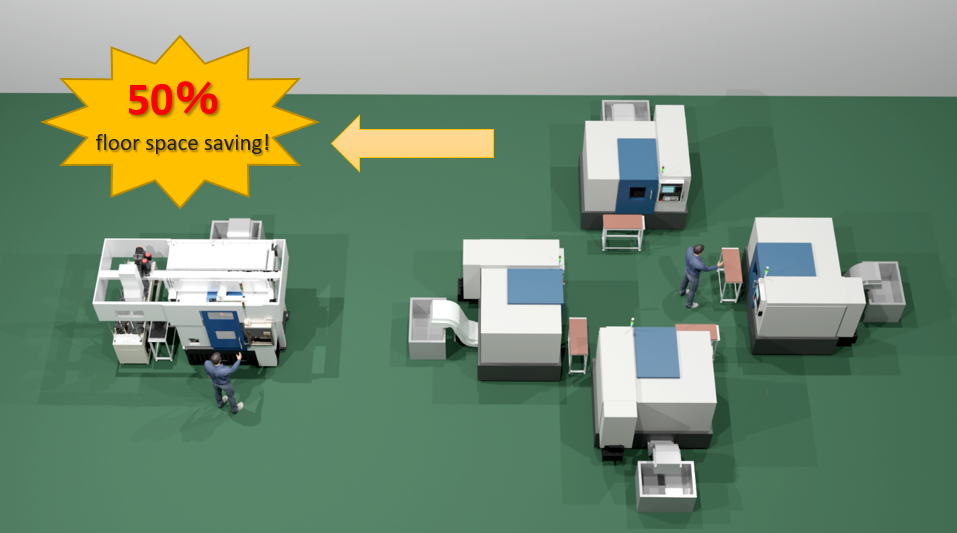

- Initially, the customer had a plan to connect the previous three machining units with robots. However, our system has enabled to save the floor space by as much as 50% compared to that plan. As a result, the productivity per unit area has increased significantly.

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

#18 Realizing a compact automated production system by consolidating four manually-operated machines into one machine equipped with a loader!

Feb 29, 2024

⛄Season’s Greetings⛄

Dec 28, 2023

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

| Company Name |

Murata Machinery, Ltd. Japanese Name : Murata Kikai Kabushiki Kaisha |

|---|---|

| Established | July 1935 |

| Main office | 136, Takeda-Mukaishiro-cho, Fushimi-ku, Kyoto 612-8418 Japan |

| Branch office (Japan) | Tokyo, Osaka, Nagoya |

| Factories (Japan) | Inuyama, Kaga, Ryuo, Oita, Ise, Gifu |

| President | Daisuke Murata |

| Products |

Textile Machinery, Machine Tools, Sheet Metal Machinery, Automated Systems, Clean FA Systems, Communication Equipment |

| Capital | JPY 900 million |

| Sales |

Consolidated: 391,800 million yen Non-Consolidated: 304,300 million yen (as of March 31, 2022) |

| Employees | 3700 [Group; 8100 ](as of April, 2022) |