#11

"We were considering upgrading the equipment, but we had no idea on how to automate the existing manual machine line to achieve the desirable benefits."

⚡Points of the problem faced by the customer⚡

1. The customer had no specialist for considering the automation of equipment in the company.

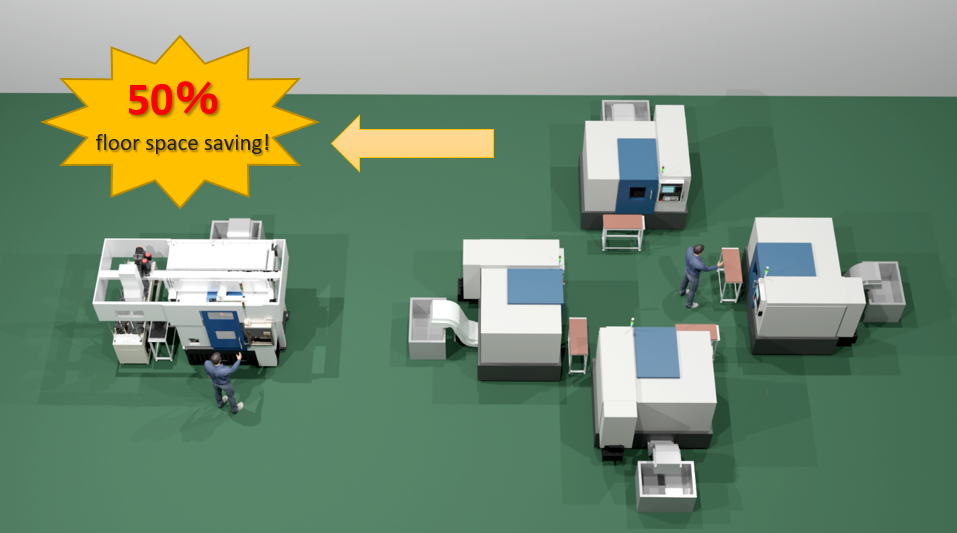

2. The machining operations were performed in three processes using two units of single-spindle lathes and one machining center. (The customer wanted to effectively utilize the limited factory space by reducing the number of machines.)

3. The production line was manually handled by operators, so there was a limit to the amount that could be produced.

In addition, since the measurement was also performed manually, the quality was inconsistent due to measurement errors or correction input errors.

💡What we can do for the customer💡

Listening to the above customer’s issues and proposing Muratec's original automation solutions!

Achieving both process integration and machining automation by installing a gantry loader on our multi-tasker MT200 Turning Center!

Our proposals to solve the customer’s problems are as follows.

📝Proposals

1. After carefully considering the situation and challenges of the customer, we have proposed our original automation solution.

Based on our wealth of experience in automation proposals, we always make the most suitable proposal for individual customers.

2. In our system, after machining of OP10 with the left-side spindle, OP20 can be also machined with the same left spindle by using an external turn around device.

In addition, OP30 is machined with the right-side spindle while the workpiece orientation is maintained in the kissing cycle.

As a result, the production line space has been saved significantly by reducing the number of machines from 3 units (3 spindles) to 1 unit (2 spindles) for the same machining operations.

3. Installation of our gantry loader has made it easy to automate a series of operations from loading/unloading to measuring.

In addition, automatic operations are performed even during lunch breaks and after regular working hours to increase production volume. Moreover, automatic feedback of the measurement results from the measuring device to the machine has enabled the product quality to be more stable than ever before.

✨Automation

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

#18 Realizing a compact automated production system by consolidating four manually-operated machines into one machine equipped with a loader!

Feb 29, 2024

⛄Season’s Greetings⛄

Dec 28, 2023

#19 Simultaneously producing two types of large workpieces with a single machine!

This is a proposal that only Muratec can offer, with a wide variety of loader cycles.

Sep 30, 2024

Opposed Twin-Spindle CNC Turning Centers dedicated to Bar Work,

Models MT1051, MT1065 and MT1065EX

Jul 10, 2024

【New Product】Front Single-Spindle CNC Turning Center 「MSR60」

Apr 17, 2024

| Company Name |

Murata Machinery, Ltd. Japanese Name : Murata Kikai Kabushiki Kaisha |

|---|---|

| Established | July 1935 |

| Main office | 136, Takeda-Mukaishiro-cho, Fushimi-ku, Kyoto 612-8418 Japan |

| Branch office (Japan) | Tokyo, Osaka, Nagoya |

| Factories (Japan) | Inuyama, Kaga, Ryuo, Oita, Ise, Gifu |

| President | Daisuke Murata |

| Products |

Textile Machinery, Machine Tools, Sheet Metal Machinery, Automated Systems, Clean FA Systems, Communication Equipment |

| Capital | JPY 900 million |

| Sales |

Consolidated: 391,800 million yen Non-Consolidated: 304,300 million yen (as of March 31, 2022) |

| Employees | 3700 [Group; 8100 ](as of April, 2022) |